Over the

past 20 years, businesses throughout North America have begun to recognize the risks associated with lower back pain (LBP), repetitive

strain injuries (RSIs) and musculoskeletal injuries (MSIs). As 3 of the most

common causes behind injury-related absenteeism and workers’ compensation

claims in North America, such injuries have a significant impact on the overall economy as businesses lose billions of dollars in lost productivity, wages, and

workplace insurance claims. In response to this development, businesses and

forklift manufacturers have begun investing in a long neglected area of

occupational health and safety – that of operator ergonomics.

How Inadequate Ergonomics Harm Your Bottom-line:

As an occupation, forklift operators are at a high risk of developing repetitive strain and musculoskeletal injuries since they spend an inordinate amount of time in a stationary or seated position. As with other professions that require employees to spend long, uninterrupted periods of time in a seated position, forklift operators are at risk of developing muscle strains, soreness and cramping in their back, neck, shoulders and arms. However, unlike their desk-bound counterparts, forklift operators are regularly subjected to additional movements and strains that exasperate an already detrimental situation.

Over the

course of a regular workday, it is not uncommon for a forklift operator to

shift into an awkward position or contort themselves in an effort to maintain

visibility while maneuvering their equipment. This is particularly prevalent in

confined, indoor workplaces as forklift operators are regularly forced to avoid

obstacles, navigate through narrow aisles and around tight corners. And, since forklifts

are designed without a suspension system, even the most basic operations tend

to subject a forklift operator to incessant vibrations and jolts. Taken

together, these two factors alone may prematurely degrade the vulnerable joints and

connective tissues of the body, as well as gradually compress the spinal column

and cause damage to the delicate discs between the vertebrae.

How Stärke Equipment Innovations Can Help:

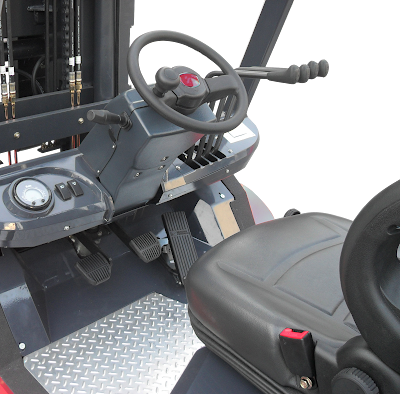

To ensure that the end of an operator’s shift is just as productive as the beginning, Stärke’s new XVI series of counterbalanced forklifts includes a number of ergonomic features and improvements when compared to other, similar models.

As part of this

systemic approach to operator comfort and safety, Stärke’s new range of XVI

forklifts also includes a number of innovative parts and components which limit the physical strain of operators even further. With a newly designed

wide-view mast system, Stärke effectively limits the health and safety risks

that result from poor visibility. To reduce

the noise and vibration, the XVI was engineered to include dampening devices

that insulate the engine and a one-piece floating cabin further reduces the

vibration felt within the operator’s compartment.

Taken as a

whole, the innovative engineering and ergonomic features included in Stärke’s

new XVI series of counterbalanced forklifts represent a categorical improvement

over other models within its class. In this way, Stärke continues to

demonstrate its commitment to develop product solutions based upon emerging

market forces, customer needs and changes to our environment. There’s strength

in numbers, and Stärke is strength.

For more information on Stärke products, pricing or availability, please contact your nearest Stärke Material Handling Dealer. Locations throughout Canada or the USA.

Local: (905)-227-7554 | Toll free: 1-877-435-4352

No comments:

Post a Comment